Likarolo tsa motsoako oa Titanium Karolo ea terekere / Mechini ea Lehlabathe la Tšepe / Tšepe e entsoeng ka Mochini / Mechini / Likarolo tsa Motlakase bakeng sa 'mele oa Compressor

| Lintho tse bonahalang | Aluminium: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Tšepe e se nang tšepe: SS201, SS301, SS303, SS304, SS316, SS430 joalo-joalo | |

| Tšepe: tšepe e bonolo / tšepe ea carbon ho kenyelletsa 1010, 1020, 1045, 1050, Q690 joalo-joalo. | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 joalo-joalo. | |

| Koporo: C11000, C12000, C12000, C17200, C72900, C36000 joalo-joalo. | |

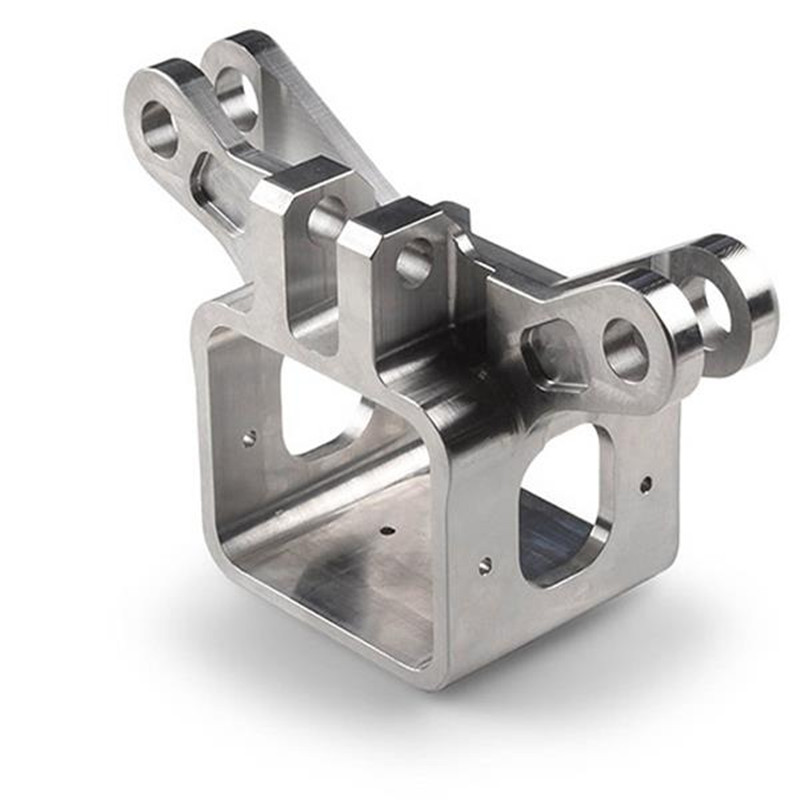

| Ho sebetsa | Jeremane Trumpf brand Laser cutter, mochini oa ho kuta oa CNC, mochini o kobehang oa CNC, |

| (CNC) mochini oa setempe, Mochini oa Hyraulic, Mochini o fapaneng oa welding, CNC setsi sa mochini. | |

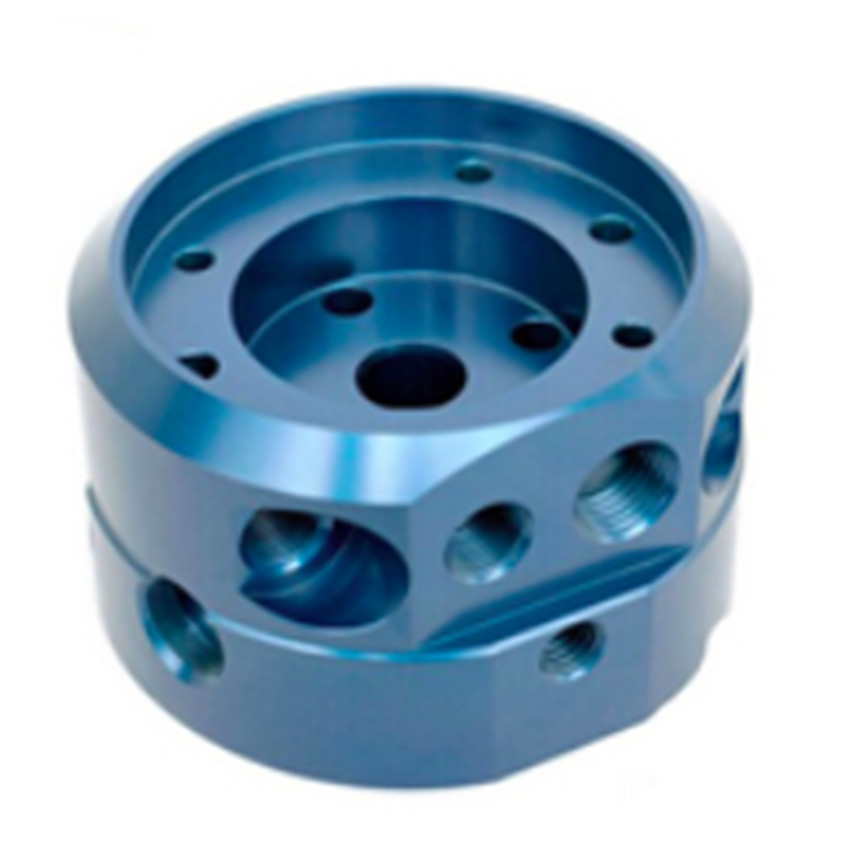

| Bokaholimo | Aluminium: Anodization, Sandblast, Brushing, polishing, Electro-plating joalo-joalo |

| Tšepe e sa hloekang: Ho bentša, ho borashe, ho feta, ho qhomisa lehlabathe, ho betla ka motlakase | |

| Tšepe: Ho roala zinki, ho penta ka niche, ho roala ka Chrome, Ho roala ka phofo, ho penta joalo-joalo. | |

| Brass & Copper: Brushing, polishing joalo-joalo | |

| Nepahalo | + - 0.1 limilimithara |

| Kopo | Terene, Auto, Truck, Medical, Mechine, Thepa, Elektronike, Motlakase jj |

Titanium ke mofuta o mocha oa tšepe.Tšebetso ea titanium e amana le litaba tsa litšila tse kang carbon, nitrogen, hydrogen le oxygen.Likahare tsa litšila tse ka har'a iodide e hloekileng ea titanium li ka tlase ho 0.1%, empa matla a eona a tlase ebile polasetiki e phahame. Thepa ea 99.5% ea titanium e hloekileng ea indasteri e tjena: density ρ=4.5g/cm3, melting point 1725℃, thermal conductivity λ=15.24W/(mK), tensile strength σb=539MPa, elongation δ=25%, shrinkage ea karolo ψ=25%, modulus of elasticity E=1.078×105MPa, hardness HB195.

Matla a phahameng

Boima ba alloy ea titanium ka kakaretso ke 4.51g / cm3, ke 60% feela ea tšepe, 'me lisebelisoa tse ling tse matla tse phahameng tsa titanium li feta matla a litšepe tse ngata tse entsoeng ka motsoako. ho feta ea lisebelisoa tse ling tsa mohaho oa tšepe, tse ka hlahisang likarolo tse nang le matla a phahameng a li-unit, tse tsitsitseng hantle le boima bo bobebe.Likarolo tsa enjene ea lifofane, skeleton, letlalo, li-fasteners le lisebelisoa tsa ho lulisa kaofela li sebelisa alloy ea titanium.

Matla a phahameng a mocheso

Mocheso oa tšebeliso ke likhato tse makholo a seng makae ho feta motsoako oa aluminium, o ntse o ka boloka matla a hlokahalang ka mocheso o mahareng, o ka sebetsa nako e telele ho 450 ~ 500 ℃ mocheso.Mefuta ena e 'meli ea motsoako oa titanium ka 150 ℃ ~ 500 ℃ e ntse e e-na le matla a khethehileng a phahameng haholo, 'me motsoako oa aluminium ka 150 ℃ matla a khethehileng a fokotsehile haholo.Mocheso oa ho sebetsa oa motsoako oa titanium o ka fihla ho 500 ℃, ha oa aluminium alloy o ka tlase. 200 ℃.

Ho hanyetsa ho hotle ha kutu

Ho hanyetsa kutu ea alloy ea titanium ho molemo haholo ho feta ea tšepe e sa hloekang moeeng o mongobo le metsing a leoatle. Ho senyeha ha pitting, corrosion ea acid, khatello ea khatello ea maikutlo e matla haholo; E na le khanyetso e ntle ea kutu ho alkali, chloride, chlorine organic products, nitric acid. , sulfuric acid, joalo-joalo Empa ho hanyetsa ho bola ha titanium ho fokotsa oksijene le chromium medium e futsanehile.

Ts'ebetso e ntle ea mocheso o tlase

Titanium alloy e ka boloka thepa ea eona ea mechine ka mocheso o tlaase le o tlaase haholo. Li-alloys tsa Titanium tse nang le ts'ebetso e ntle ea mocheso o tlaase le likarolo tse tlaase haholo, tse kang TA7, li ka boloka polasetiki e itseng ho -253 ℃.Ka hona, alloy ea titanium e boetse ke ea bohlokoa thepa ea sebopeho sa mocheso o tlase.

Mosebetsi o phahameng oa lik'hemik'hale

Lihlahisoa tsa alloy tsa Titanium

Lihlahisoa tsa alloy tsa Titanium

Titanium e na le lik'hemik'hale tse matla tsa lik'hemik'hale tse nang le O2, N2, H2, CO, CO2, mouoane oa metsi, ammonia le likhase tse ling sepakapakeng. mocheso o phahame, sebaka se thata sa TiN se tla thehoa ka ho sebelisana le N. Botebo ba lera le thata le le brittle holim'a metsi le hlahisoang ke ho monngoa ha khase bo ka fihla ho 0.1 ~ 0.15 mm, 'me tekanyo e thata ke 20% ~ 30%.Titanium lik'hemik'hale tsa lik'hemik'hale le tsona li kholo, ho bonolo ho hlahisa ho khomarela le khohlano. bokahodimo.

E nyenyane mocheso conductivity elasticity

Thermal conductivity ea titanium (λ=15.24W/(m·K)) e ka ba 1/4 ea nickel, 1/5 ea tšepe, 1/14 ea aluminium, le mocheso oa mocheso oa titanium e fapaneng. li-alloys li ka tlase ho 50% ho feta tsa titanium. The elastic modulus ea titanium alloy e ka bang 1/2 ea tšepe, kahoo ho tiea ha eona ho futsanehile, ho bonolo ho fetoha, ha ea lokela ho etsoa ka molamu o mosesaane le likarolo tse tšesaane tse nang le marako, ho khaola ha ts'ebetso ea bokaholimo ba rebound e kholo, hoo e ka bang makhetlo a 2 ~ 3 a tšepe e sa hloekang, e bakang likhohlano tse matla, ho khomarela, ho roala sekhomaretsi holim'a sesebelisoa.