Lihlahisoa

-

Lahlela flange ea koporo

tlhahiso ea lihlahisoa:

Flange e boetse e bitsoa flange kapa flange boenjiniere ba liphaephe bo tloaelehileng haholo, li-flange li sebelisoa ka bobeliLiphaephe tsa khatello e tlaase li ka kopanngoa le flange ea terata.Welding flange e sebelisoa bakeng sa khatello ea ho feta 4kg. Beha gasket pakeng tsa li-flange tse peli ebe u li koala fatše.

Li-flanges tsa khatello e fapaneng li na le botenya bo fapaneng 'me li sebelisa liboutu tse fapaneng.

Lipompo le li-valve, ha li hokahane le phala, likarolo tsa lisebelisoa tsena li boetse li etsoa ka sebopeho se lumellanang sa flange, se tsejoang hape e le khokahanyo ea flange.

Ka kakaretso ka lifofane tse peli sebakeng sa tšebeliso ea liboutu le likarolo tse koetsoeng tsa khokahano, hangata li bitsoa "flange", joalo ka khokahano ea phala ea moea, likarolo tsa mofuta ona li ka bitsoa "karolo ea flange".

Threaded flange ke mofuta oa flange.The threaded flange connection structure is an assembly, which is composed of para of flanges,' maloa bolts, nuts le gasket.

Selelekela sa Sehlahisoa:

1/2"--30" flange e khoele

Litekanyetso tsa China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

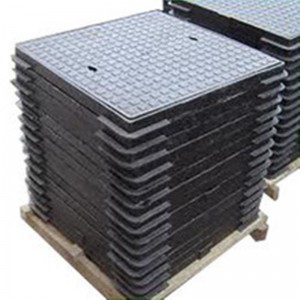

Likoahelo tsa mokoti

tlhahiso ea lihlahisoa:

Good toughness.Boleng ba tšusumetso bo tšoana le ba tšepe ea carbon e bohareng, e leng makhetlo a fetang 10 a thepa ea tšepe e bohlooho.

Tekong ea kutu e matla ea metsi, palo ea kutu matsatsing a 90 ke 1/40 feela ea phala ea tšepe le 1/10 ea pipe ea tšepe e bohlooho. linako tsa phala e tloaelehileng ea tšepe.

Plastiki e ntle.Elongation ≥7%, e ts'oanang le tšepe e phahameng ea k'habone, empa elongation ea thepa ea tšepe e bohlooho ke zero.

Matla a phahameng.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa li tšoana le tšepe e tlaase ea carbon le makhetlo a mararo joaloka lisebelisoa tsa tšepe tse bohlooho.

Ka lebaka la nodular graphite microstructure, tšepe ea ductile e molemo ho feta tšepe e entsoeng ka tšepe ho fokotsa matla a ho sisinyeha, kahoo ho molemo haholo ho fokotsa khatello ea kelello.Lebaka la bohlokoa la ho khetha tšepe ea ductile ke hore tšepe ea ductile e theko e tlaase ho feta ea tšepe.Theko e tlaase ea ductile. tšepe e etsa hore thepa ena e ratoe haholoanyane, e sebetse hantle, 'me e se ke ea bitsa chelete e ngata mochining.

Matla a tšepe ea ductile a tšoana le a tšepe e entsoeng ka tšepe.Tšepe ea Ductile e na le matla a phahameng a lihlahisoa, e nang le matla a fokolang a 40K le matla a lihlahisoa tsa tšepe tse entsoeng ka tšepe ea 36K feela. boholo ba likopo tsa masepala joalo ka metsi, metsi a letsoai, mouoane, joalo-joalo.

-

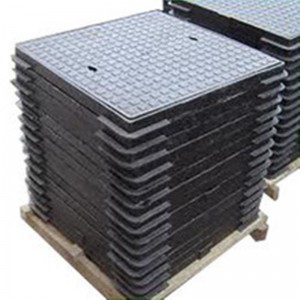

Likoahelo tsa mokoti oa tšepe

tlhahiso ea lihlahisoa:

Good toughness.Boleng ba tšusumetso bo tšoana le ba tšepe ea carbon e bohareng, e leng makhetlo a fetang 10 a thepa ea tšepe e bohlooho.

Tekong ea kutu e matla ea metsi, palo ea kutu matsatsing a 90 ke 1/40 feela ea phala ea tšepe le 1/10 ea pipe ea tšepe e bohlooho. linako tsa phala e tloaelehileng ea tšepe.

Plastiki e ntle.Elongation ≥7%, e ts'oanang le tšepe e phahameng ea k'habone, empa elongation ea thepa ea tšepe e bohlooho ke zero.

Matla a phahameng.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa li tšoana le tšepe e tlaase ea carbon le makhetlo a mararo joaloka lisebelisoa tsa tšepe tse bohlooho.

Ka lebaka la nodular graphite microstructure, tšepe ea ductile e molemo ho feta tšepe e entsoeng ka tšepe ho fokotsa matla a ho sisinyeha, kahoo ho molemo haholo ho fokotsa khatello ea kelello.Lebaka la bohlokoa la ho khetha tšepe ea ductile ke hore tšepe ea ductile e theko e tlaase ho feta ea tšepe.Theko e tlaase ea ductile. tšepe e etsa hore thepa ena e ratoe haholoanyane, e sebetse hantle, 'me e se ke ea bitsa chelete e ngata mochining.

Matla a tšepe ea ductile a tšoana le a tšepe e entsoeng ka tšepe.Tšepe ea Ductile e na le matla a phahameng a lihlahisoa, e nang le matla a fokolang a 40K le matla a lihlahisoa tsa tšepe tse entsoeng ka tšepe ea 36K feela. boholo ba likopo tsa masepala joalo ka metsi, metsi a letsoai, mouoane, joalo-joalo.

-

Li-grate tse ikhethileng

tlhahiso ea lihlahisoa:

Li-grizzley grates ke sehlopha sa li-grate tse entsoeng ka tšepe tse sebelisetsoang ho koahela li-grates, likoti, le li-grate tse ling tse sireletsang tse sireletsang tšireletso ea motho kapa ho sireletsa lifate le lintho tse ling tse sireletsang ho senya.

Li-gratings ke li-gratings tsa pula, lifate tsa lifate, li-grate gratings, li-floor gratings, joalo-joalo.Ka mohlala, li-grate tsa tšepe li atisa ho behoa holim'a metsi a matloana a ho hlapela, ho lumella metsi ho phalla le ho thibela likotsi tsa maoto le maoto.

-

Resin e koahela

tlhahiso ea lihlahisoa:

1. Ts'ebetso e matla e khahlanong le bosholu: sekoaelo sa mokoti se kopantsoeng se sebelisa resin e sa tsitsang, fiber ea khalase le lisebelisoa tse ling le skeleton e matlafalitsoeng e kopantsoeng ke ts'ebetso e khethehileng ea tlhahiso, kamora mocheso o phahameng le ho hatella bakeng sa ho theha, boleng ba ho nchafatsa thepa, ho thata haholo ho tlosa tšepe ea tšepe (ho ntša boleng ba litšenyehelo tsa tšepe ho feta tšepe) kahoo ke ea ts'ebetso e sebetsang e khahlanong le bosholu.

2. Bophahamo bo boholo ba ho beleha: botlaaseng ba mohaho o khethehileng oa pitsa e ka tlaase, e le hore sebaka se hatelitsoeng se eketsehe ka makhetlo a leshome kapa esita le makhetlo a mangata. Fiber e matlafatsang e tsoelang pele e sebelisoa ho etsa bonnete ba hore fiber fiber le lesela la fiber ea khalase li kopantsoe ka boitsebiso, e le hore sehlahiswa se be le bokgoni ba ho jara bo lekaneng.Le ho kopana kapa ho feta maemo a naha.

3. Bophelo ba nako e telele ea tšebeletso, ka ho amoheloa ha resin e phahameng ea ts'ebetso, fiber ea khalase le foromo e khethehileng, mokhoa oa tlhahiso ea tlhahiso ea ho etsa bonnete ba hore ho kenella ha li-resin ka fiber ea khalase, ho ntlafatsa haholo molamu oa lithupa, ho etsa thepa tlas'a cyclic loading, ha e hlahise ka hare. tshenyo, e le ho etsa bonnete ba bophelo ba tšebeletso ea sehlahisoa, le sekoahelo se seng sa resin composite manhole se nang le melemo e ts'oanang.Felisa litšitiso tsa bofokoli ba ho khomarela.

4. E ntle ebile e sebetsa, boemo bo phahameng: Ho ea ka litlhoko tsa bareki ba maemo a holimo, re ka etsa Logo e rarahaneng le mebala e sa tšoaneng holim'a sekoahelo se le seng sa sekoahelo sa motho ka mong, e le hore mohlala o be bonolo, mebala e khanyang, distinct.'Me e ka etsoa ho ea ka tlhokahalo ea bareki le mefuta eohle ea majoe a majoe a tšoanang le majoe a etsisang holimo le 'mala.

5. Ho hanyetsa mocheso o phahameng / o tlaase, ho thibela mocheso o motle le ho hanyetsa ho matla ha kutu: ho hanyetsa ho bola, ho se chefo le ho se kotsi.Ha ho na lisebelisoa tsa tšepe, tse bapaloang maikutlo a sebele a ho kenya letsoho.E ka sebelisoa libakeng tse rarahaneng, tse fetohang, tse thata le tse hlokang. Lihlahisoa li 'nile tsa lekoa ke litsi tse amehang tsa naha tse nang le matla a ho hlahloba, tse nang le acid e hlakileng le khanyetso ea alkali, ho hanyetsa kutu, ho thibela botsofali le lipontšo tse ling li fihlile le ho feta litekanyetso tsa naha.

6. Tšireletso ea tikoloho, anti-skid, lerata le tlaase: sehlahisoa se ke ke sa thella, ha ho lerata le bohale le ntho e sa tloaelehang ka mor'a hore koloi e tsamaee. , hlola sekoaelo se seng sa tlhahlobo "tlola, stilt, molumo, phalliso" le mathata a mang.

-

Flange e tloaelehileng

tlhahiso ea lihlahisoa:

Flange e boetse e bitsoa flange kapa flange boenjiniere ba liphaephe bo tloaelehileng haholo, li-flange li sebelisoa ka bobeliLiphaephe tsa khatello e tlaase li ka kopanngoa le flange ea terata.Welding flange e sebelisoa bakeng sa khatello ea ho feta 4kg. Beha gasket pakeng tsa li-flange tse peli ebe u li koala fatše.

Li-flanges tsa khatello e fapaneng li na le botenya bo fapaneng 'me li sebelisa liboutu tse fapaneng.

Lipompo le li-valve, ha li hokahane le phala, likarolo tsa lisebelisoa tsena li boetse li etsoa ka sebopeho se lumellanang sa flange, se tsejoang hape e le khokahanyo ea flange.

Ka kakaretso ka lifofane tse peli sebakeng sa tšebeliso ea liboutu le likarolo tse koetsoeng tsa khokahano, hangata li bitsoa "flange", joalo ka khokahano ea phala ea moea, likarolo tsa mofuta ona li ka bitsoa "karolo ea flange".

Threaded flange ke mofuta oa flange.The threaded flange connection structure is an assembly, which is composed of para of flanges,' maloa bolts, nuts le gasket.

Selelekela sa Sehlahisoa:

1/2"--30" flange e khoele

Litekanyetso tsa China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Pipe ea tšepe ea tšepe

tlhahiso ea lihlahisoa:

Flange e boetse e bitsoa flange kapa flange boenjiniere ba liphaephe bo tloaelehileng haholo, li-flange li sebelisoa ka bobeliLiphaephe tsa khatello e tlaase li ka kopanngoa le flange ea terata.Welding flange e sebelisoa bakeng sa khatello ea ho feta 4kg. Beha gasket pakeng tsa li-flange tse peli ebe u li koala fatše.

Li-flanges tsa khatello e fapaneng li na le botenya bo fapaneng 'me li sebelisa liboutu tse fapaneng.

Lipompo le li-valve, ha li hokahane le phala, likarolo tsa lisebelisoa tsena li boetse li etsoa ka sebopeho se lumellanang sa flange, se tsejoang hape e le khokahanyo ea flange.

Ka kakaretso ka lifofane tse peli sebakeng sa tšebeliso ea liboutu le likarolo tse koetsoeng tsa khokahano, hangata li bitsoa "flange", joalo ka khokahano ea phala ea moea, likarolo tsa mofuta ona li ka bitsoa "karolo ea flange".

Threaded flange ke mofuta oa flange.The threaded flange connection structure is an assembly, which is composed of para of flanges,' maloa bolts, nuts le gasket.

Selelekela sa Sehlahisoa:

1/2"--30" flange e khoele

Litekanyetso tsa China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Likarolo tse entsoeng ka tloaelo

tlhahiso ea lihlahisoa:

Mochini oa forging o sebelisetsoa ho hlahisa deformation ea polasetiki ka ho hatella tšepe e se nang letho ho fumana forging ka thepa e itseng ea mochini, sebopeho le boholo. ho kopanya ka har'a ingot ho fetoha ho kopana haholoanyane, 'me thepa ea polasetiki le ea mechine ea tšepe e ntlafatsoa.Lisebelisoa tsa phala ea Forging haholo-holo li akarelletsa ho forging flange, forging recing pipe, forging tee, joalo-joalo Thepa e ka sehloohong ea lisebelisoa tsa phala e entsoeng ke Q235, Q345, 16Mn. ,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, jj ho latela litlhoko tsa mokelikeli o itseng ebe o tšeloa ka har'a hlobo, ka mor'a ho tiisa ho pholile, banna ba fumana sebopeho se reriloeng esale pele, boholo le ts'ebetso ea likarolo tsa ho lahla (kapa blank) ts'ebetso.[1]

-

Ho theha peipi ea tšepe

tlhahiso ea lihlahisoa:

Mochini oa forging o sebelisetsoa ho hlahisa deformation ea polasetiki ka ho hatella tšepe e se nang letho ho fumana forging ka thepa e itseng ea mochini, sebopeho le boholo. ho kopanya ka har'a ingot ho fetoha ho kopana haholoanyane, 'me thepa ea polasetiki le ea mechine ea tšepe e ntlafatsoa.Lisebelisoa tsa phala ea Forging haholo-holo li akarelletsa ho forging flange, forging recing pipe, forging tee, joalo-joalo Thepa e ka sehloohong ea lisebelisoa tsa phala e entsoeng ke Q235, Q345, 16Mn. ,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, jj ho latela litlhoko tsa mokelikeli o itseng ebe o tšeloa ka har'a hlobo, ka mor'a ho tiisa ho pholile, banna ba fumana sebopeho se reriloeng esale pele, boholo le ts'ebetso ea likarolo tsa ho lahla (kapa blank) ts'ebetso.[1]